The Masons Mitre,

With its roots in stone masonry the masons mitre joint has evolved a commonly used joint in kitchen renovation where it is used to join bench tops together at a 45 degree angle

The masons mitre was originally used where two stone members met at a 45 degree angle and it was created by removing a small section of material from one part, thereby creating a socket for the other.

In masonry terms, this allows the bond of the masonry courses to to continue around a corner without a staggered vertical joint and and allows the mortar to truly bed into the corner of the joint.

In the cabinetmakers world the masons mitre allows for a strong and attractive joint, particularly on bench tops with rounded edges, and saves on the wastage of materials and additional labor costs that would result from the removal of large triangular sections that need to be cut in a traditional mitre joint.

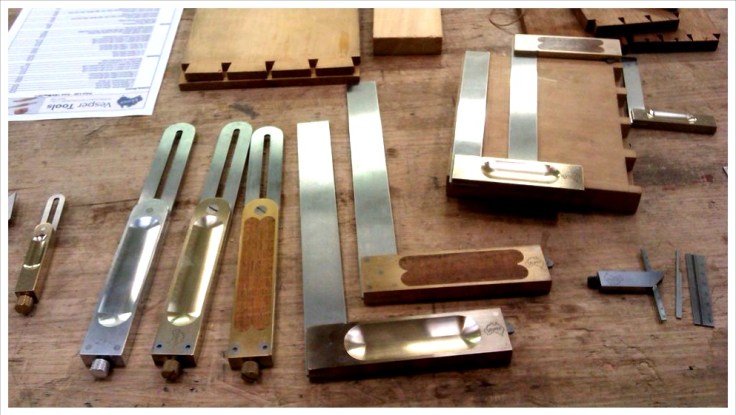

The masons mitre joint can be a it of a challenge, but with a bit of practise and good jig for your router it’s quite achievable.

One of the best jigs I’ve used to achieve this joint is the APS 900 jig which is made by Festool. Whilst it looks a bit complex it’s actually fairly straight forward and gives you accurate and repeatable results.

Have a look at the video here from Festool TV where Festool demonstrator Frank Jaksch shows the how to use the APS 900 along with a Festool OF 2200 router to create a masons mitre joint.

It is dubbed in English and the picture is a bit dodgey at times but please persist, it is worth watching.

Anyways guys, I hope you enjoyed the video and if your not using it already, will soon be adding the masons mitre to your arsenal of joinery.

Thanks for reading and as always your comments and feedback are appreciated.

Be safe and have fun,

Cheers

Bryan