The Waxing Process,

As an aspiring bookbinder for a couple of years now I’m always on the hint for interesting and innovative ways to cover and decorate the handmade books and journals that we make.

A few months ago whilst shopping in Fitzroy, Victoria for some endpapers for a commission journal that my daughter and I were making for a client, we happened across some beautiful handmade papers from Nepal which featured embedded dried flowers and the had most awesome texture. We settled on a few sheets for the commission and grabbed another couple of pages for play.

The Nepalese paper we bought is called Lokta Paper and is made from the dense fibrous bark of the Nepalese paper plant or Lokta bush. The Lokta Bush regenerates every 4 to 6 years after being harvested and cut about 6 inches from the ground. This tree free paper provides a viable revenue stream for nepalese artisans in urban and rural areas.

The Lokta plants fibres are long and supple and result in a soft paper which takes colouring and decoration beautifully and has a beautiful deckled edge when torn.

For our bookbinding applications we primarily used the lokta paper as endpapers in books and I found that it works best if backed with 125 gsm acid free cartridge paper. To mount the lokta paper we use an archival grade flexible PVA adhesive.

I decided to try the lokta paper as a book covering materials for some tape bound hand sewn journals that I had designed as I wanted them to have an elegant, handmade feel about them. I knew that the raw lokta paper was not going to be strong enough to withstand repeated handling so I knew I needed to come up with a simple organic finish to protect and enhance these beautiful papers.

I drew on my woodworking and object conservation experience and decided that as the lokta paper was an organic material, lacquers and varnishes were not going to cut it so I settled on an organic wax from an Australian manufacturer to protect the papers.

When I worked as a furniture maker I used to make a wax based on a combination of beeswax and canuba wax on the furniture I made, then I discovered Cabinet Makers Wax made by Gilly Stephenson in Western Australia.

I quickly decided that my limited workshop time was better spent making furniture rather than making wax so I decided to run with the Gilly Stephenson product.

This wax gives a beautiful lustrous and soft finish and durable finish on timber and It can be buffed to a high shine so I felt the chance it would work on fibrous papers would be very good.

I knew that I needed to to some tests to check how well the wax would work so I backed some samples of lokta paper on to 125 gsm acid free cartridge paper using an archival flexible PVA adhesive then when dry, mounted the samples to pre sanded 9mm plywood blocks.

I backed the lokta paper on to cartridge paper to give it more strength to withstand the buffing during the waxing process and to limit the translucency of light coloured lokta paper when being placed on a darker substrate.

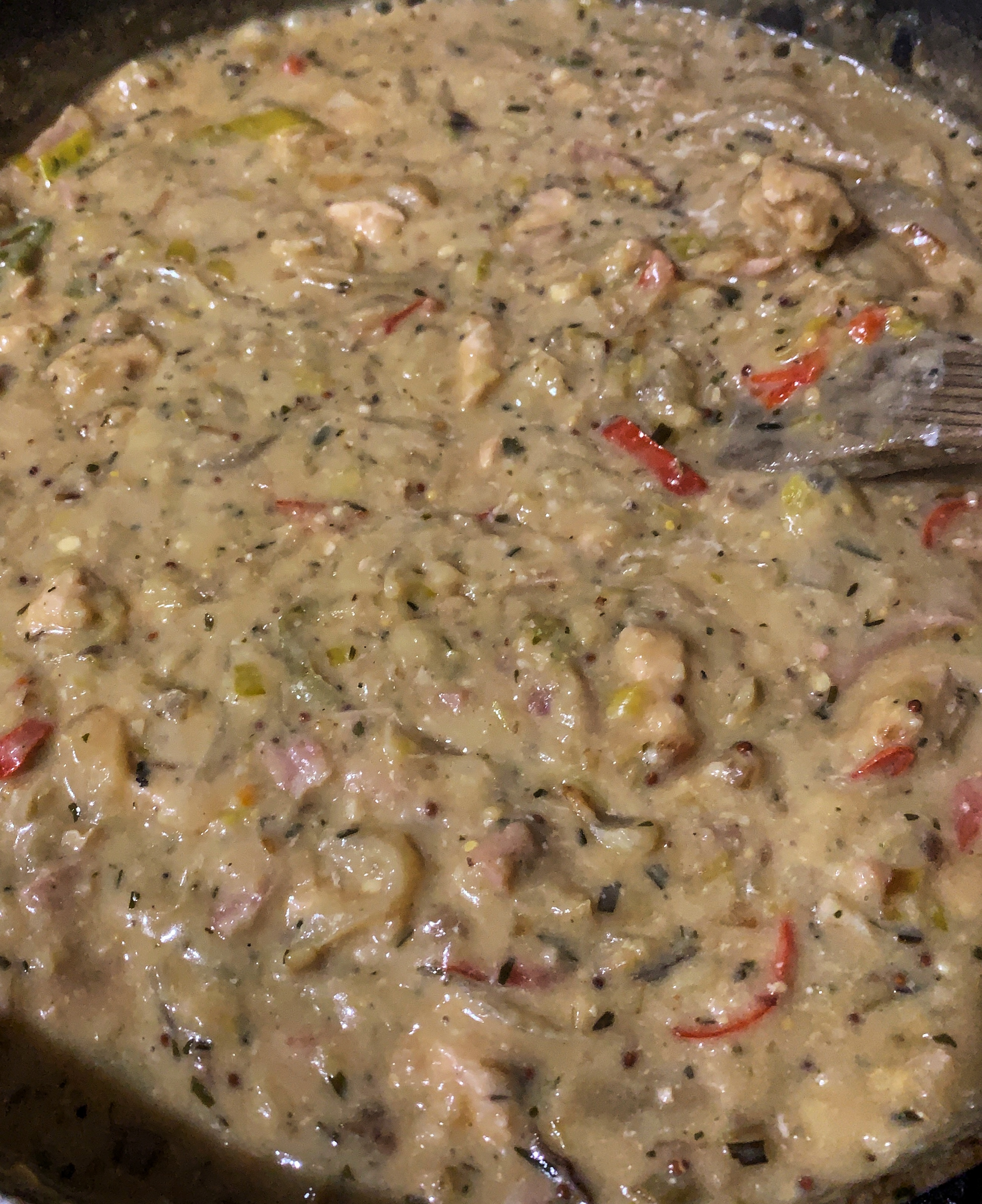

The top photo shows the lokta paper prior to waxing and the bottom photos show the paper after two coats of wax have been applied.

The cabinet makers wax is a combination of beeswax and canuba wax in a gum turpentine base.

Beeswax on its own is never fully dries and can become highly tacky in hot climates.

Canuba wax on its own is extremely hard to use in its natural state

Combining the two in a gum turps base gives you a building wax which dries to a durable finish which can be buffed to a high shine and with repeated applications builds a flat surface which enhances the natural texture of the surface its been applied to.

I waxed the samples applying two coats of cabinet makers wax over a 24 hour period and was absolutely stoked with the results.

The natural texture and colour of the paper was enhanced by the finish and the samples had a beautiful feel in hand.

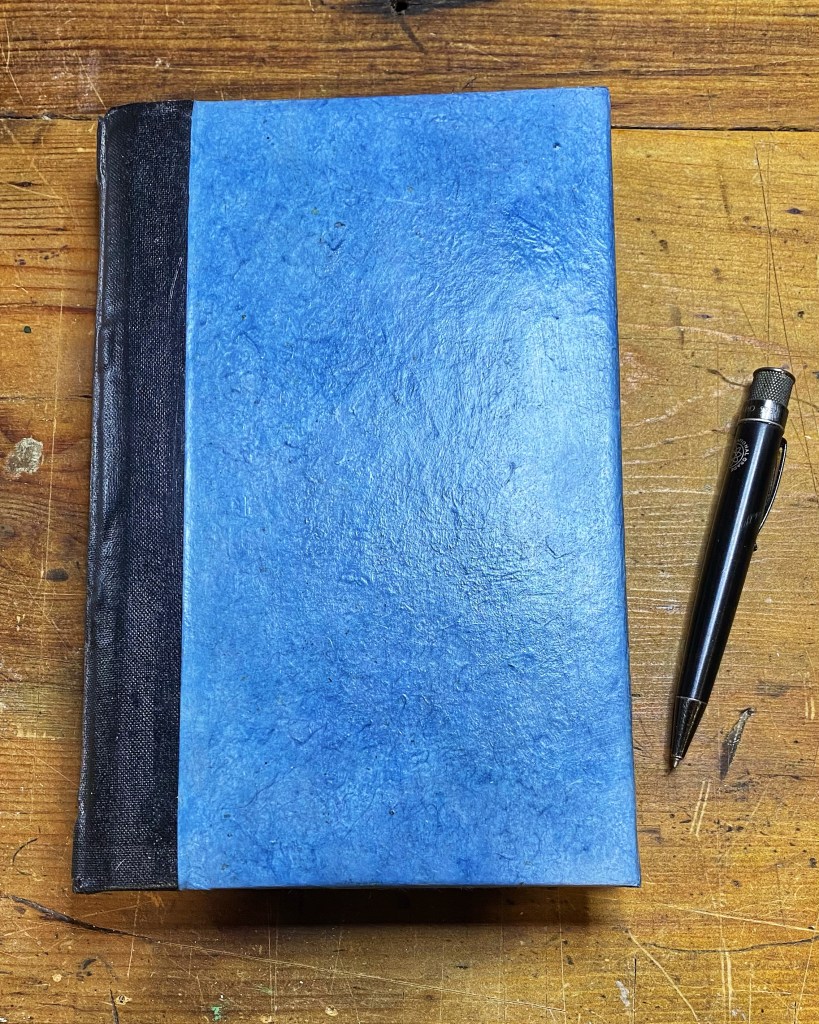

Project Blue Book

The book in the photo shown above is a A5 tape bound hand sewn journal. It features a waxed indigo blue lokta paper cover.

We’ll use this book as an example of the waxing process.

We’ve put together a paper waxing kit which is available from our Etsy store

The waxing kit contains a can of the Gilly Stephensons Cabinet Makers Wax as well as 2 150mm polishing pads and a buffing brush

To begin the process you’ll need a piece of cotton cloth to apply the wax to your piece. I use a piece of old cotton beset cut into a piece about 8 inches square. Fold the cloth the gather a small amount of wax to the paper on your workpiece. If you’re finishing a book cover with a book cloth spine as in the example shown here, you may wish to mask the spine to avoid getting the wax on the book cloth.

Watch the video here for the first step of the process.

Keep applying small amounts of wax to the paper until the surface is covered with a thin coat t of wax. Always remember, it’s better to apply a couple of thin coats rather than one thick coat. This is one of those instances where less is more…

When you’ve applied a thin coat to the paper let it cure for two to four hours, then use one of the white polishing pads to rub back the excess wax from the surface of the paper. Use light stroke with not too much pressure to bring the surface up. As you progress you should begin to see the surface develop. Apply a second coat of wax to the surface then leave it it for around six hours .

When the wax has cured buff the surface lightly with the white pad, then switch to the buffing brush and using gentle but rapid strokes, buff the covers of the book

Watch the third video here fore more details on the technique:

That should about cover it. Please don’t hesitate to contact me if you have any questions about the content shown here.